Engineering Services

Our dedicated engineering team will collaborate with you, assisting in the design and development of custom solutions meeting your specific requirements. Interfacing directly with your technical team, we will gather all relevant information and maintain constant communication throughout the process.

The custom-designed solutions we offer have helped our customers improve quality, reduce costs, aid maintenance, and enhance safety.

Custom Designed Solutions

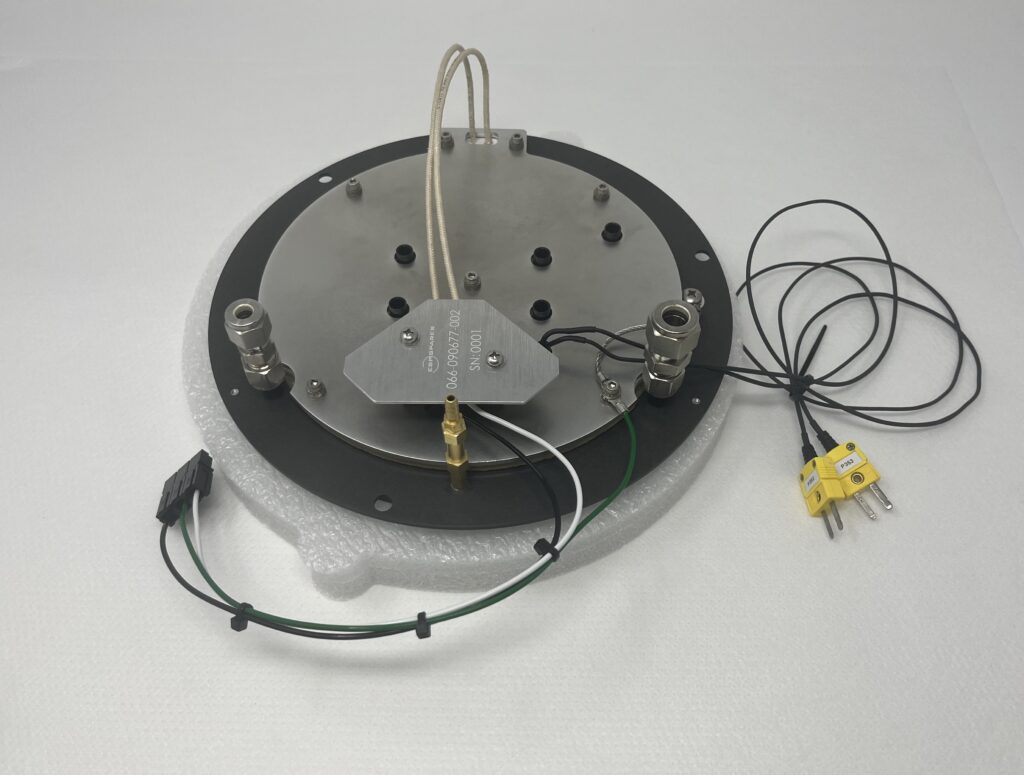

Product Spotlight: UV Bake Thermochuck

The original manufacturer of this thermochuck, Axcelis, no longer supports these 200mm UV Gemini Photostabilizer tools. If you don’t want to make a costly upgrade to new tools, ESP offers the entire assembly new! ESP machines and assembles these in-house with a domestic supply chain, so no need to worry about tariff-related costs!

Learn more and read product specifications at this dedicated web page:

Axcelis Gemini Photostabilizer Thermochuck Replacement

Design Improvements

Our engineers analyze existing designs to identify opportunities for enhanced performance, manufacturability, and reliability. We deliver refinements that cut costs, extend product life, and improve user experience.

Case Study: ESD Lift Pins

The original equipment manufacturer’s design had an issue with electrical arcing to the wafer. Arcs could cause mechanical damage to the lift pin, and breaking or popping on bare silicon wafers. ESP’s design has an electrically conductive plastic tip that discharges any static buildup in a controlled way. As an added benefit, the life of the metal component is prolonged because only the plastic tip is replaced over time.

3D Printed Prototypes

Bring ideas to life quickly with our in-house 3D printing capabilities. We produce functional prototypes for fit checks, design validation, and rapid iteration—accelerating your development cycle.

Unique Designs

When off-the-shelf just won’t cut it, our engineering team delivers purpose-built solutions tailored to your exact needs. From specialty fixtures to complex assemblies, we combine deep technical expertise with practical manufacturing insight to create one-of-a-kind solutions for your unique challenges.

Case Study: Patent-Pending EBR Flow Sensor for Sabre Tools

The Sabre Edge Bead Removal (EBR) flow switch output was either “flow” or “no flow” and did not have detectable flow deviations. Specific flow rates could cause line breaks or nozzle damage, leading to wafer scrap. The ESP redesign converted the flow switch to a flow sensor. Benefits include:

- Ability to collect flow data to chart and trend over time

- Set limits and interlock tool when deviation occurs

- Plug and play install

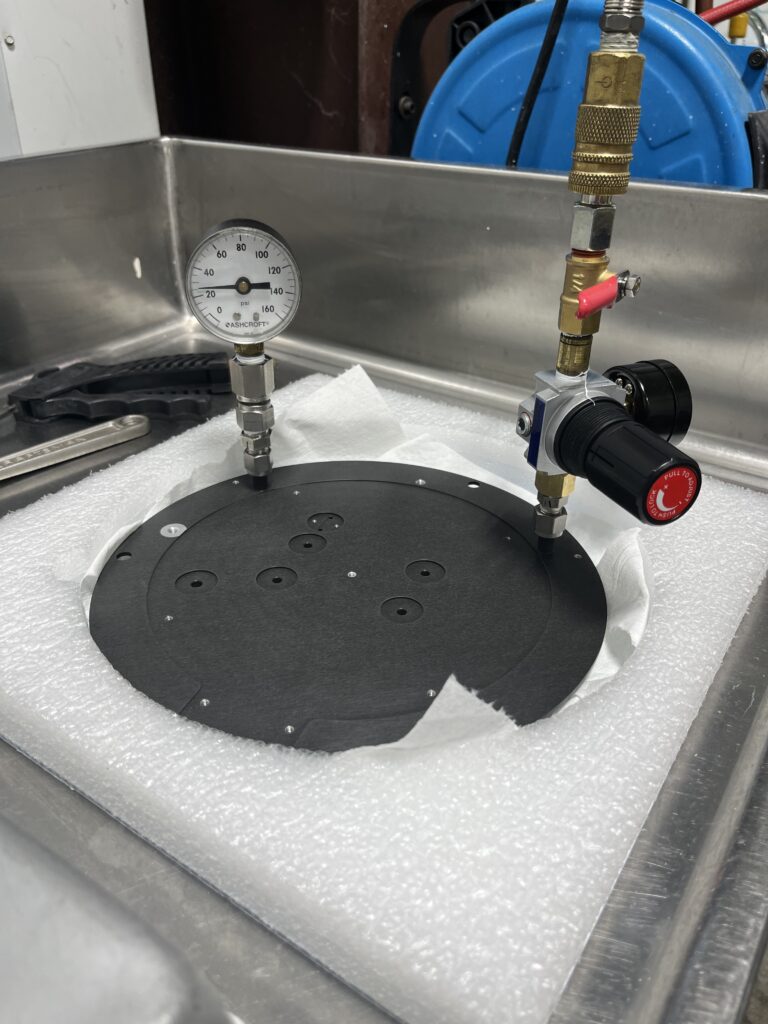

Functional Testing

We design and build testing solutions to validate your components under real-world conditions. Whether verifying performance, durability, or compliance, our functional tests give you confidence before production or deployment.

The following examples of functional tests can be performed on finished parts or assemblies as needed:

- Pressure Tests

- Hydrostatic

- Pneumatic

- Vacuum

- Electrical Resistance

- Mechanical Actuation

- Wafer Chucking

- Wafer Flatness

- Wafer Concentricity

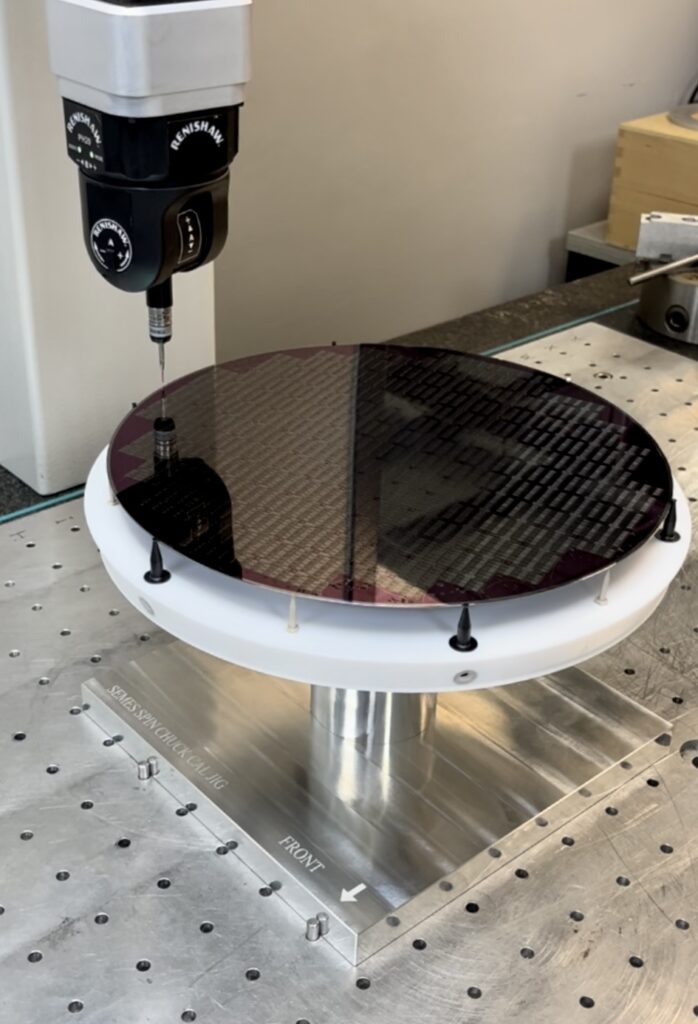

Calibrations

Our custom calibration tools and procedures ensure repeatable accuracy over time.

Case Study: Iris Spin Chuck Calibrations

Our onsite coordinate measurement machine allows us to accurately measure wafer flatness and concentricity relative to the chuck. ESP engineers can then adjust the wafer chuck pin position to achieve tight tolerances.

Controlling concentricity properly can eliminate wafer streaks.

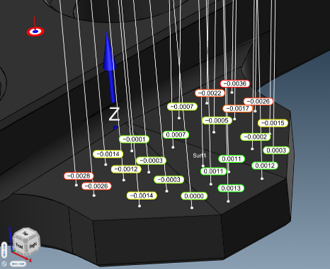

Dimensional Analysis

Our precision measurement services provide detailed dimensional data to render a thorough digital model of your physical parts. We use advanced tools and methods, alongside engineering expertise, to develop manufacturing tolerances that are practical for both the application and the machining capabilities. Manufacturing drawings are drafted to ensure every part meets exact specifications.

Additional analyses, such as surface microtexture, are available to aid in research or development of new or existing products and processes.

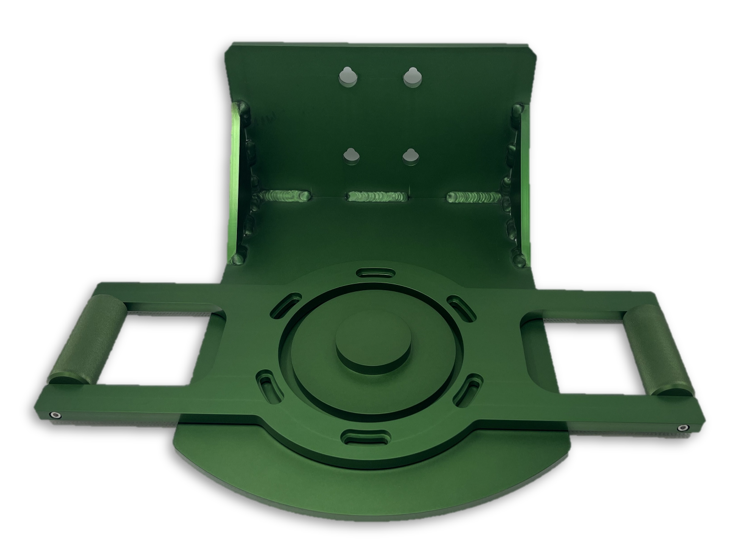

Maintenance Jigs

We design maintenance jigs that make servicing equipment faster, safer, and more consistent. Our jigs are built to withstand shop-floor conditions and improve workflow efficiency. They typically improve ergonomics as well. For example, lifting heavy objects or accessing equipment at odd angles.

Reverse Engineering Process

ESP’s reverse engineered parts follow a rigorous process to ensure parts are consistent with the OEM quality, and in many ways we are able to make improvements and changes that extend the life of the part.

Here’s how we do it: